Devices currently on the market must offer customers more than just very good technical performance or reliability to be successful. Nowadays, customers demand that a product look attractive, so electronics manufacturers are outdoing themselves in upgrading the design of their products. This includes displays and touch panels used in most market segments – from medical applications to transportation and industrial automation. Today, fine-tuning the display to match the customer’s application is more important than ever. An excellent solution in such a case is customization, i.e. adapting the module to the needs of the ordering party. Below we describe the possibilities for changing parameters and the process from idea to execution.

Table of Contents

POTENTIAL GAINS FROM CUSTOMIZATION

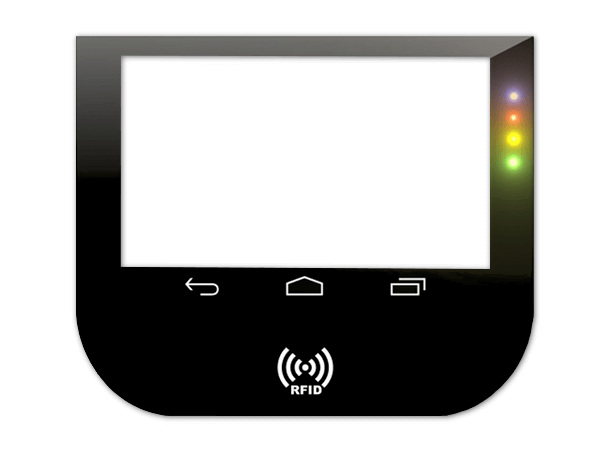

Making a personalized module should be considered by any manufacturer of devices equipped with a display integrated with a touch panel. The use of customized solutions (display + touch panel) allows designers almost unlimited possibilities in determining the external appearance and functionality of end applications. This solution allows the display and touch panel to be matched to the final application (e.g., dashboard, washing machine, control device), rather than the other way around. The possibilities and cost of manufacturing customized panels are now much more affordable. In addition, customization companies often offer technical support and assistance at every stage of the project, resulting in additional savings on the client’s side. A product made in this way features an attractive design and has software and hardware tailored to the customer’s application, making the final application much more attractive in the eyes of the end user.

CUSTOMIZATION PROCESS

Step 1 – General requirements

In addition to the products themselves, some companies selling displays also offer professional assistance in creating a design and producing a complete solution (touch panel + display) based on customer requirements. At the very beginning of the customization process the customer presents the customization service provider with basic information about the application and general requirements related to the technical parameters of individual components.

Step 2 – Interview and details

In the next stage, it is important for the engineer who is handling the project to conduct an interview regarding the target device. The purpose of such an interview is to obtain as much detail as possible, so that all elements of the module are adapted to the operating environment of the final application. At first, the information needed is the external dimensions of the touch panel, a description of its shape, type of structure and thickness. The most common material used to cover the display and touch sensor is glass. Advantages of this material include. durability (application-matched glass thickness) and a design that fits many applications and environments. It is also possible to grind the edges of the glass so that the corners are rounded and/or so called. C-cut, or rounding of the glass sheet. Another customization option is to make holes in the glass for mechanical components, e.g. buttons, ignition. In addition, the customer at this stage determines the details of the touch panel painting (color, logos, descriptions, icons). It is also possible to choose a full-color or translucent mask, which allows light to pass through from underneath, and without illumination remains the color of the background. The most common icons to be made visible while the device is running are made this way. Additional customization options such as anti-reflective coating , resistance to water, electromagnetic interference or vandalism, give the touch panel new functionality. In addition to the touch panel, a complete kit most often consists of a properly matched display. Based on preliminary data provided by the customer regarding display technology (Mono LCM, OLED, TFT, e-paper), diagonal, resolution, operating temperature range, brightness and additional functionalities (water, dust, shock and electromagnetic field resistance, etc.), engineers also propose a display model that meets the customer’s specified requirements.

Step 3 – Quotation and detailed drawing

Once the initial design is determined, the panel company prepares a design quote and commercial offer. Depending on the complexity of the project, the process takes up to 5 working days. After the customer approves the preliminary design, the manufacturer draws up an accurate detailed manufacturing drawing of the panel. The drawing of the panel takes into account all the necessary dimensions and the shape specified by the customer. At this stage, minor changes are often made, e.g. changing icons, logos. In this case, all modifications are applied to the design until full customer approval is obtained, i.e. until the drawing is signed by the ordering party.

Step 4 – Produce a prototype (sample)

Once the project is signed, the factory is almost ready to start making a small batch of samples. However, before samples are produced, the manufacturer very often requires payment of an NRE (Non-Recurring Engineering) fee, commonly known as tooling. This fee covers the cost of preparing the production line to produce the module according to the design and the cost of producing the samples that the customer will receive for testing. After receiving the samples, the purchaser is obliged to test them. At this stage, any irregularities can still be addressed without incurring large costs. If the test batch conforms to the requirements, the customer places a production order.

Step 5 – Proper production

Once samples are approved, the lead time for a production batch is generally 8 – 10 weeks. Once done the full process allows you to order the product multiple times without incurring additional costs again. It is also possible to apply changes between batches. It should then be remembered that any change in the design may involve an NRE fee or a change in the unit price of the panel. Depending on the complexity of the application and other parts being customized, production volumes can start as low as a few pieces for large panels.

For additional information, please feel free to contact us.

2018-01-09

Recent Knowledge

Internet of things, what it is and examples of industrial applications

The Internet of Things (IoT) is one of the most promising and rapidly developing technologies of recent years. Its application in business brings great opportunities to optimize processes, reduce costs […]

Stains, discoloration, stripes on the screen – how to identify and repair defects in industrial displays?

The dark spot on the iPhone screen, the black spot on the TV, the colored spots on the phone screen, the yellow spot on the display … Problems with screens […]

Basic electronic components in industry – a guide for beginners

Electronics has played an extremely important role in all branches of modern industry for many years. It allows automation of production processes, precise control of machines and equipment, collection and […]

Optoelectronics – basic information and example applications

Optoelectronics is the branch of electronics that deals with the conversion of electricity into light and light into electricity using semiconductor materials called semiconductors. Semiconductors are crystalline solid materials with […]